Iron and Steel making

Nozzles for the surface finish

Process

Process

Below are some of the applications we support with our spray nozzles for the surface finish process.

Applications

We have spray nozzles for:

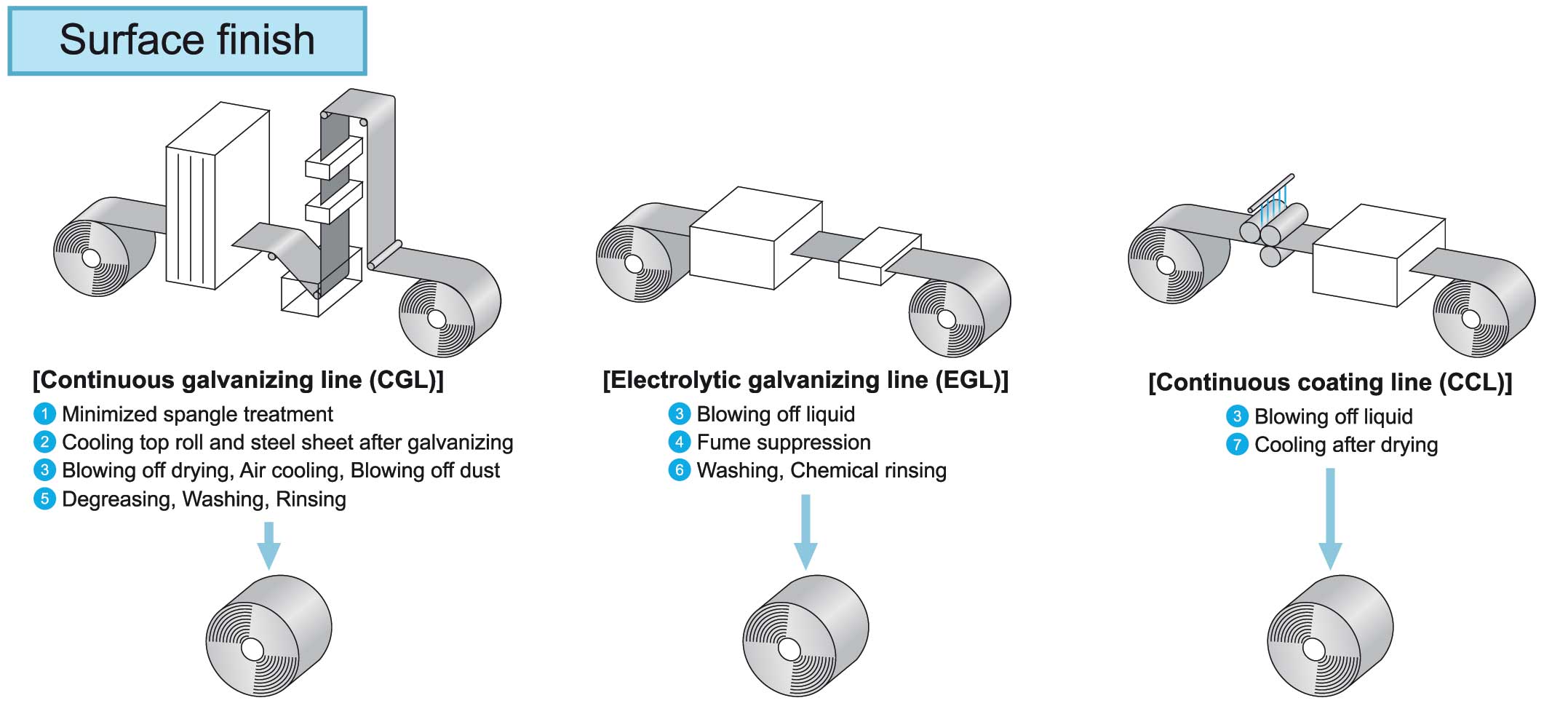

Continuous galvanizing line (CGL)

- Minimized spangle treatment

- Cooling top roll and steel sheet after galvanizing

- Blowing off drying, Air cooling, Blowing off dust

- Degreasing Washing, Rinsing

Electrolytic galvanizing line (EGL)

- Blowing off liquid

- Fume suppression

- Washing, Chemical rinsing

Continuous coating line (CCL)

- Blowing off liquid

- Cooling after drying

Focused solutions

- For cooling after galvanizing (CGL): Fine fog spray

- For blowing off (CGL; EGL; CCL): Air nozzles

Solutions

Benefits

- BIM series for cooling top roll and steel sheet

- Pneumatic nozzle with 3 spray pattern possible (flat, hollow cone and full cone spray)

- Unique design minimizes clogging and offers longer product life

- Produces fine atomization with mean droplet diameter of 100 μm or less

- BRASIKan® for degreasing and rinsing:

- Spray header with internal brushes to clean clogged nozzles

- Ideal where maintenance is difficult to reach

- Uniform and even spray distribution for uniform rinsing

- Maintenance downtime reduced

- Better productivity with a reliable operation without interruption

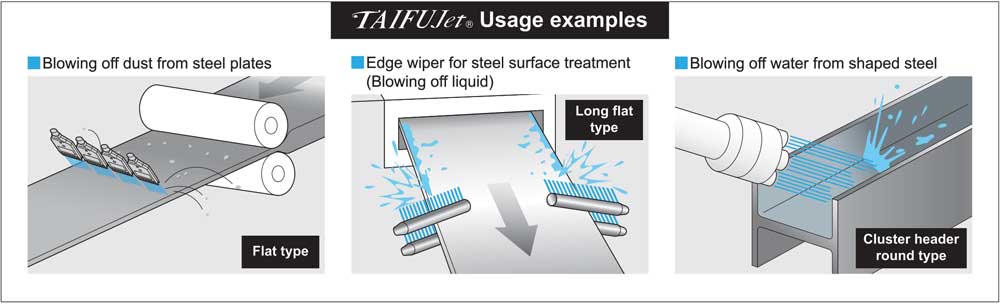

- TAIFUJet series for as blowing off nozzles for drying, removing dust and liquid:

- Air booster nozzles for air cooling, blowing off, stripping, cleaning, air blow transport

- 3 nozzle shape: flat, long flat and round type

- Noise level reduced by 10 dB compared to a conventional one-hole air nozzle with the same air volume

- Uniform air flow resulted from the unique design

- High impact for the solid stream air nozzle for pinpoint blowing

Download the Iron and Steel making documents:

- Solutions based brochure: download