Iron and Steel making

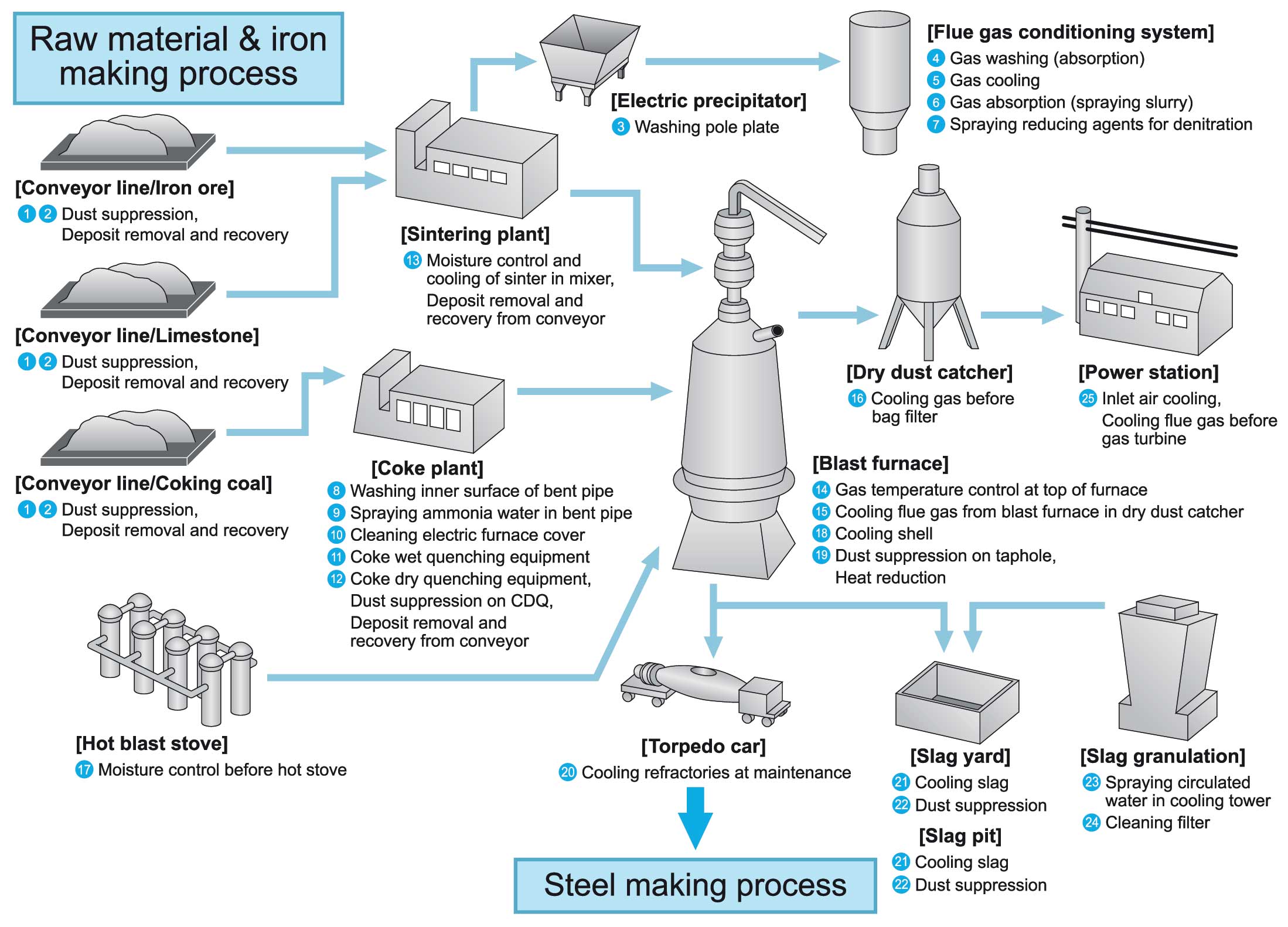

Nozzles during iron making process

Process

Process

Below are some of the applications we support with our spray nozzles during each step of the iron making process.

Applications

We have spray nozzles for:

- Dust suppression

- Exhaust gas cooling

- Cooling refractories

- Gas absorption

- Cooling flue gas from blast furnace in dry dust collector

- Heat reduction

- Spraying

- Cleaning

- etc.

Focused solutions

- For dust suppression, exhaust gas cooling and cooling refractories: Fine fog pneumatic spray nozzle

Solutions

Benefits

- For all applications: high-quality nozzles

- Controlled quality with inspection

- Guaranty of performance for hydraulic nozzles in terms of spray capacity and spray angle.

- With the GSIMII series nozzle:

- Used in cooling tower to cool down flue gas with a large capacity of fine fog

- Used for dust suppression around exit of rolling mill to prevent particle contamination on the end product

- Used for cooling refractories

- For gas absorption in flue gas desulfurization and spraying in cooling tower, the TAA series nozzle is a lightweight wear-resistant flange type nozzle which sprays a stable hollow cone spray pattern under low pressures.

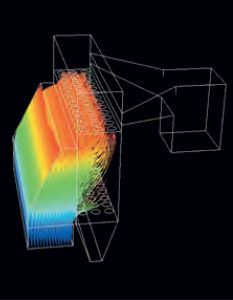

- For gas cooling solution, we offer additional measurement and simulation like thermo-fluid analysis data or spray impact distribution across width and thickness.

Download the Iron and Steel making documents:

- Solutions based brochure: download