Pollution Control

Exhaust gas cooling nozzles

Process

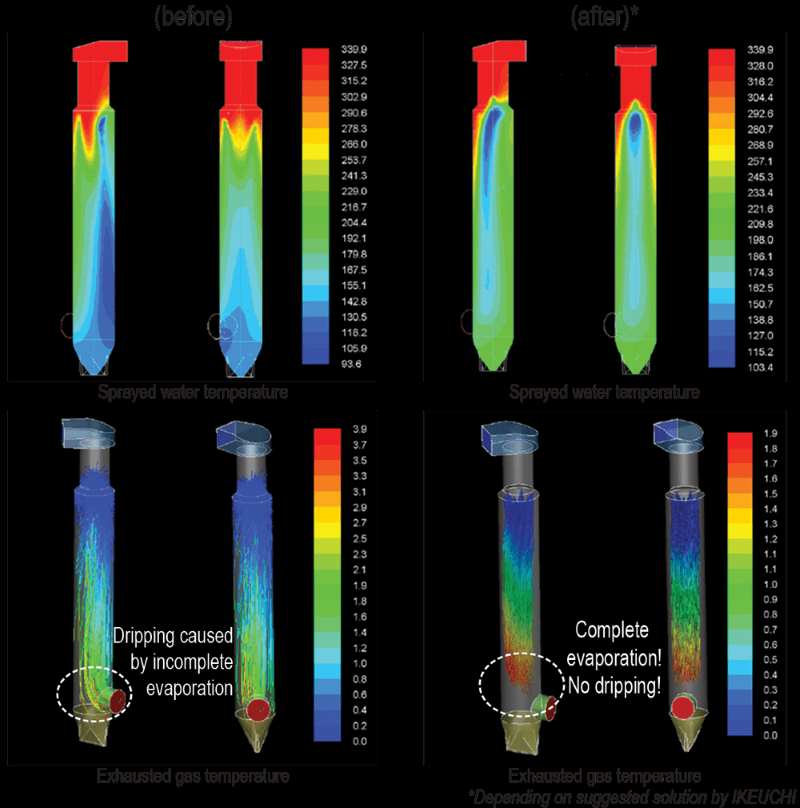

Common issues with Gas Cooling process

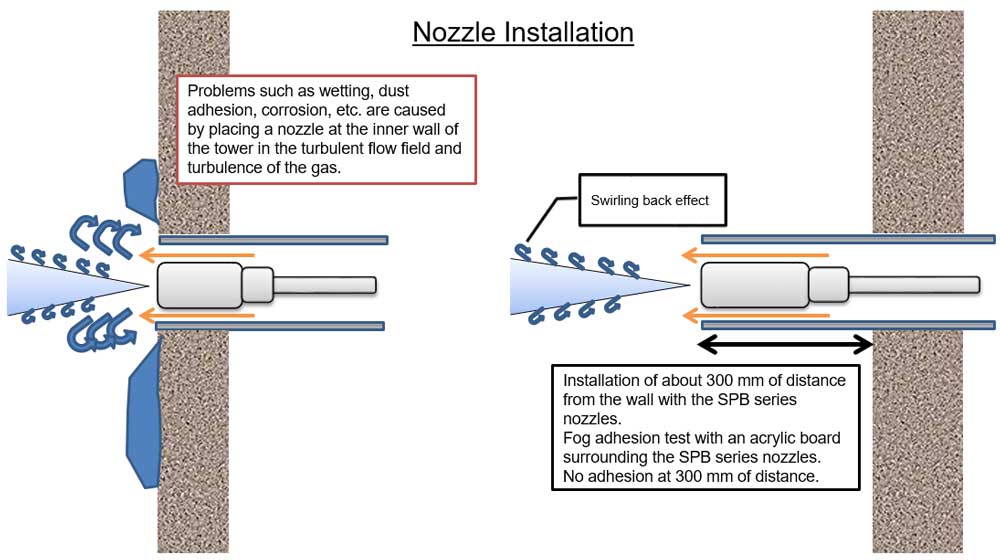

- Clinker issue for cooling tower and nozzles

- Risk of corrosion

- Nozzles dripping (excess water)

- Problems caused by dust adhesion to interior walls or around outlet of gas cooling tower

- In an installation where the gas and sprayed water is coming from the top of the tower:

- Unvaporized-water drainage needed from the lower part of the tower due to excess water

Solution: Innovative Gas Cooling Nozzles

We understand the significance of droplet size and full evaporation in gas cooling towers to ensure maximum cooling effect without extra drainage.

Therefore, we have a wide range of nozzles with different droplet sizes, spray capacities and spray angle to suit every request.

Customers realize lower running costs and minimal maintenance downtime with our clog-resistant nozzles and wide range of material options.

Example of Systems / Products used for gas cooling nozzles

- ASPB series – Air-assisted Spillback Nozzles [NEW]

GSIMII series Fine Fog Pneumatic Spray Nozzles

SPB series Spillback Nozzles

Solutions

Benefits

- Effective cooling with full evaporation

- Minimal maintenance downtime

- Lower running costs

Advantages of the solution

- Clog-resistant nozzles

- Wide range of material options like for anti-corrosion Titanium material, Hastelloy® or other

- Wide range of spray capacity with minimal variation in droplet sizes and excellent atomization

- Energy-saving nozzles with a low consumption of compressed air

- For an installation of the nozzle horizontally from the side, the high-velocity fog reaches the center of the gas cooling tower without being disturbed by the exhaust gas flow

- Other efficient installation is possible with different angle / positioning of the nozzle based on our recommendation and your plant’s layout

Other applications for these nozzles

- Cooling: Gas, moldings, refractories, incinerators (flue gas desulfurization), cement factories, glass factories, blast furnaces, iron works, blast furnaces (dry dust catcher)

- Moisture control: Flue gas, concrete, paper, cardboard, blast furnaces (water spraying to hot blast stove)

- Combustion: Oil, waste fluid

- Chemical reaction: denitration

- Iron making process: Cooling flue gas before gas turbine, Cooling refractories at maintenance, Dust suppression at casting of pig iron

- Steel making process: Cooling converter shell at maintenance, Flue gas cooling on electric furnace, Dust suppression at casting of steel

- Rolling mill and surface finish process: Cooling flue gas from heating furnace, Dust suppression on rolling mill outlet