Automotive

Dust suppression in the Painting / Inspection line

Process

Issues faced without dust suppression in the sanding, buffer zone / storage, and transport line

- Static Charge: Dust-related defects

- Airborne contamination (fibers, dust particles, etc.)

- Working environment affected by the heat

Solution: Dust suppression and humidification

We offer large and small scale, whole room or spot humidification though our direct and efficient humidification systems. Our humidification and spraying systems can also suppress dust and prevent electrostatic charges (ESD) and dust adhesion. By preventing electric static charges and suppressing airborne particles (micro fibers, dust particles, paint particles, etc.), we can reduce dust-related defects, the losses from defect products, and repair costs. Our systems will also improve the working environment by reducing ambient heat.

Example of Systems / Products used for this solution

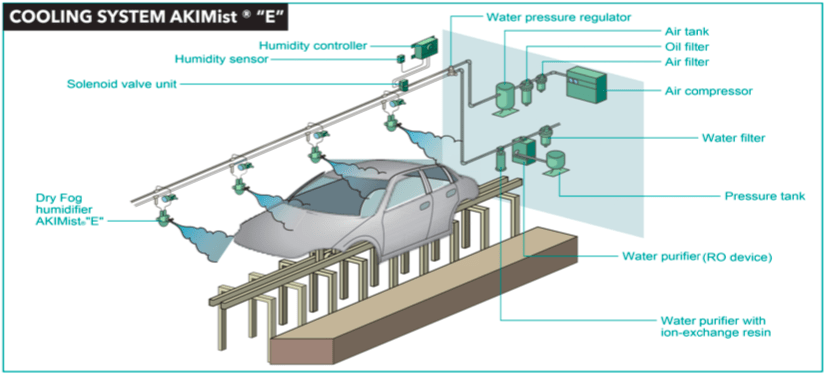

AirAKI® Dry Fog humidifier system

Example of an installation of Dust suppression solution

Solutions

Benefits

- Reduce or avoid dust related defects

- Prevent ESD

- Prevent electrostatic charges

- Increase productivity

- Non-wetting solution

- Spot humidification (avoid large scale installations)

- Improve ambient temperatures

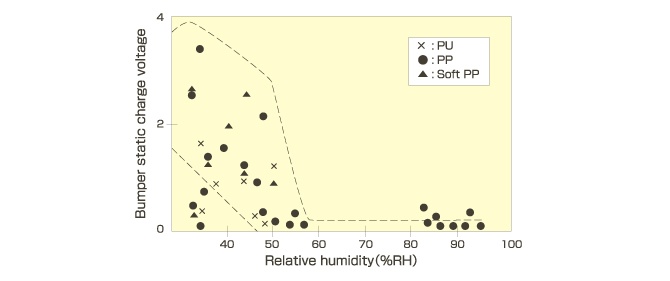

Relation between humidity level and static charge

Advantages of this solution

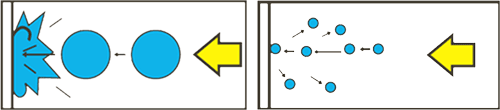

- Dry Fog = no wetting the objects in the working environment thanks to the diameter of the water droplets

Difference between small droplet size and bigger droplet

- No moving parts + no clogging = no maintenance when using DI water and clean air

- Dust suppression through atomization

- Add-on to existing HVAC

- Easy to install

- Shut-off individually

- Low running costs

Applications

- Maintain the proper level of humidity for electronics mounting process for brake systems, car navigation, power windows, power steering as well as painting/coating processes.

- Dust suppression and humidification in all stages of the automotive manufacturing facilities

- Ambient cooling of worker zones

- Improve setting and curing of paint, resins and adhesives through humidification

- Other applications: humidification, indoor cooling, outdoor cooling