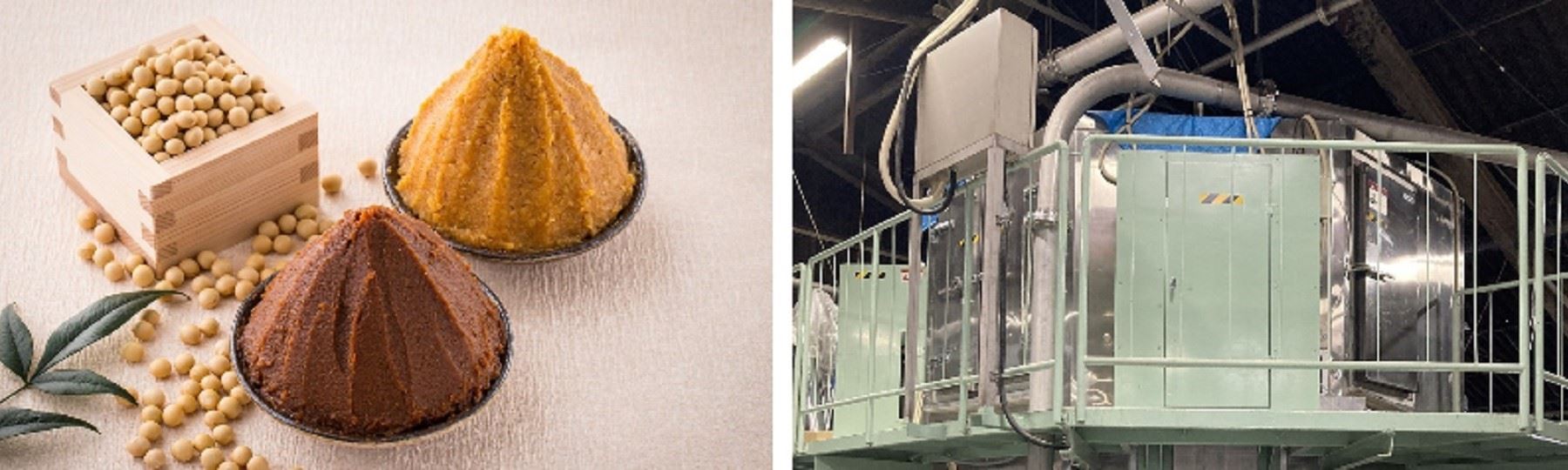

Tank cleaning for miso paste production process

Regular cleaning of fermentation tanks is essential to uphold hygiene standards and to maintain a consistent result in flavour and quality. However, food producers often face the challenges of a lot of manual labour going into the cleaning process of fermentation tanks. By automating the tank cleaning process, a lot of time can be saved for other tasks and the cleaning result will always be the same.

The problem

A miso paste manufacturing company was facing problems with its daily cleaning of fermentation tanks. One employee would spend an average of 2 hours to manually clean the very sticky tanks every 2-3 days. There was a request to reduce the cleaning time and use this added time for other tasks in the production.

The solution

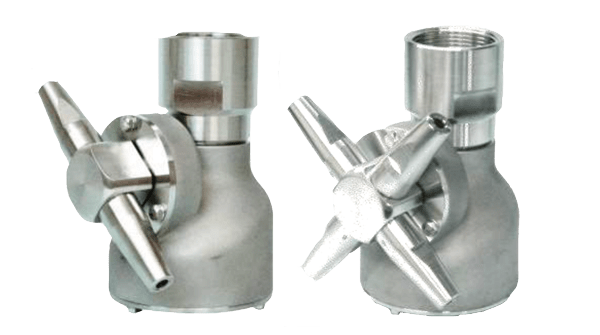

After consulting with the engineers at Ikeuchi Japan, they selected a 3D rotating tank cleaner from the RJ series. Furthermore, Ikeuchi conducted field tests using a sample machine and confirmed that the expected cleaning effect could be achieved.

The result

Manual work has been replaced by automatic cleaning, and a process that took two hours has been shortened to about 10 to 20 minutes, significantly reducing the workload. This also contributed to resolving labor shortages and freed up valuable time for other production work. By using a three-dimensional rotating nozzle, it is now possible to clean the inner wall of the tank almost completely in all directions, and only final finishing work is required. By being able to clean with warm water, protein stains can be thoroughly removed and any remaining odors have been eliminated. The customer was very satisfied with the result.

Still not sure which tank cleaner is most suitable for your specific application? Try our tank cleaner selection guide here

Are you ready to dive more into the specifications of each tank cleaner?