Edge wiping process improvement with TAIFUJet®

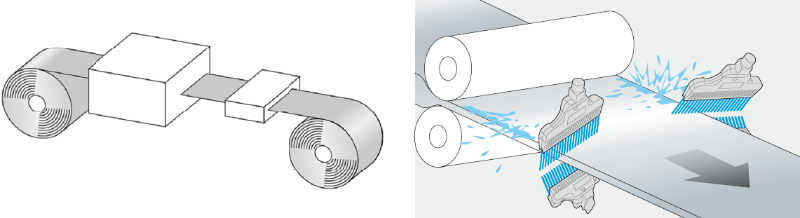

A Japanese steel manufacturer had issues with insufficient water removal during the edge wiping process. Edge wiping is a process used to remove excess coatings from the edges of steel strips, such as aluminum, zinc etc.). This process ensures a uniform coating thickness across the strip and prevents different issues like coating buildup, drips etc.

The problem

A Japanese steel mill had an issue during edge wiping (water removal from the edges of steel plates). This process was performed using general-purpose air nozzles in the steel plate surface treatment process after cold rolling. However, because the air nozzles were fixed to target both ends of a specific width of steel plate, there was an issue of insufficient water removal. For example, when a narrow steel plate was flowing in, the nozzles on both ends would target the outside of the width of the steel plate, and the air would not hit the edges, resulting in poor water removal.

When poor drainage occurs, the color of the plating becomes uneven on the surface, and even minor defects leave water stains on the surface. This problem occurs about five times a week at its peak, and the customer consulted Ikeuchi Japan to find a solution.

The solution

The effective spray width of our standard air nozzle is 42mm, but since this was not sufficient in this case, Ikeuchi Japan designed a custom product that widens this to 100mm. This allows for a wider drainage width which could solve the issue of the customer.

Furthermore, Ikeuchi Japan proposed a layout in which these wide nozzles were placed symmetrically at multiple locations in the flow direction of the steel plate, with different width intervals. With this layout, the outer nozzles are used when the steel plate width is wide, and the inner nozzles are used when the steel plate width is narrow, allowing for flexible response even when the plate width changes.

The 100mm custom-made air nozzle solution

Are you looking for a similar solution or your own custom-made solution for the steel industry?

Then contact us for a non-binding consultation.

Also check out our catalog with other spray nozzle solutions for the steel industry: