Large capacity fine fog, energy-saving design

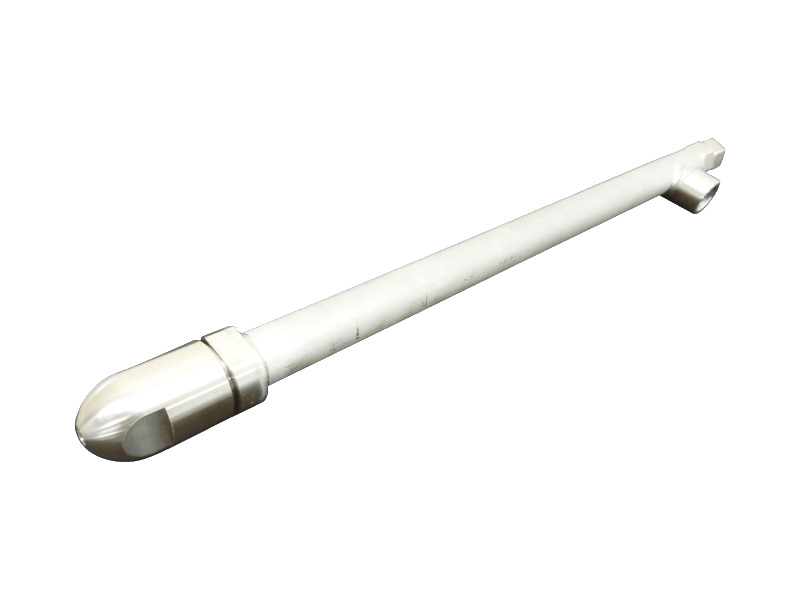

GSIMII series

Features

The GSIM II series nozzles’ features:

- Full cone pneumatic spray nozzle producing a large amount of “fine fog”.

- Energy-saving design – mean droplet diameter of 50 μm and a maximum droplet diameter of 150 μm (*4) at an air-water ratio of 130.

- Large turn-down ratio.

- Spray angle of 20° or 60°.

*1) Measured at compressed air pressure of 0.2 – 0.5 MPa (ca. 2 bar – 5 bar) and liquid pressure of 0.2 – 0.5 MPa (ca. 2 bar – 5 bar).

*2) Measured at compressed air pressure of 0.2 – 0.5 MPa (ca. 2 bar – 5 bar).

*3) Free passage diameter of liquid inlet for GSIMⅡ 60° spray angle type.

*4) Measured by Laser Doppler Method.

Thread standard

-

Pipe conn. size

Liquid inlet: Rc 3/8" - Rc 3/4", Air inlet: Rc 3/8", Rc 1/2"

Standard pressure

-

Spray angle

20°, 60°

Spray capacity

15 - 2,000 L/hr (*1)

Supply air type

Compressed air

Liquid feeding system

Liquid pressure

Mean droplet diameter

30 - 80 μm

Air consumption

150 - 4,000 L/min, Normal (*2)

Air pressure

-

Free passage diameter

1.8 - 4.0 mm (*3)

Applications

The GSIM II series nozzles have multiple applications:

- Cooling: Gas, moldings, refractories

- Moisture control: Gas, concrete

- Combustion: Oil, waste fluid

- Dust suppression: Recycling facilities, material facilities, moldings

- Iron making process: Cooling flue gas before gas turbine, Cooling refractories at maintenance, Dust suppression at casting of pig iron

- Steel making process: Cooling converter shell at maintenance, Flue gas cooling on electric furnace,

- Dust suppression at casting of steel

- Rolling mill and surface finish process: Cooling flue gas from heating furnace, Dust suppression on rolling mill outlet

More information?

Do you want to order this product? Or request a quote?