Compressed Air Driven Nozzles – Other

The air nozzles product division is classified into the following categories: compressed air driven nozzles and air blower driven nozzles. These categories distinguish from one another based on how the air is supplied towards the nozzle and require different installations due to that fact. Because of their unique properties, a certain air nozzle category is indicated to be implemented for a particular set of applications.

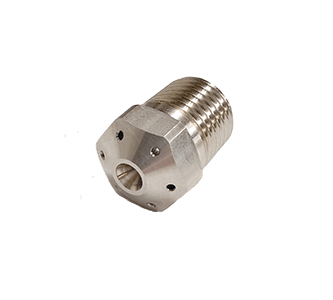

For compressed air driven nozzles, the air supply comes from the production of compressed air generated by the powered compressors that release the air at a stable pressure. The compressed air is incorporated in the compressed air nozzles as their fundamental manner of air blow booster.

Selecting and utilizing IKEUCHI’s technical air nozzles provides you with a great advantage compared to free exhaust pipes: they require a lower consumption of compressed air flow. Thus, the installation’s operating costs are decreased, and implicitly, your energy costs are reduced.

Types of Compressed Air Driven Nozzles:

The nozzles from this category can be divided based on their pattern of spraying:

- Flat Jet: HF series;

- Round Jet: CCP-A series;

- Slit Jet: VZ series, SLNHA-H series; SAP series;

- Air Amplifier: EJA series.

A general overview

We developed the IKEUCHI air nozzles to maximize the blowing efficiency. The wide range of models offers the possibility to choose the most suitable nozzle for each application, optimizing the required blowing force and airflow. This complete design decreases the cost of compressed air and provides better control of blowing accuracy for each application.

Flat, compact, round, we offer several shapes of nozzles’ orifices for different applications, such as:

- drying;

- blowing off particles;

- cooling;

- cleaning;

- rejection of objects;

- air curtain; etc.

Each product is specialized to types of applications, depending mostly on their design as a compressed air nozzle. The flat design is recommended for uniform objects that do not contain sharp angles, bend, or concave/convex surfaces. This is thanks to its alignment of nozzle orifices and intake holes that provide a uniform impact distribution. For the round design, this is applied in cases where pieces have irregular shapes or recesses. The nozzles from this category have the orifices arranged in a circle that leads to directing a round blowing pattern. Regarding the slit design, some nozzles are suited for tight spaces and smaller equipment, while are optimal to cover large spaces thanks to their wide angle. In this case, the wide flat blow or uniform sheet of air is developed from a thin slit nozzle orifice.

The material from which the nozzles are fabricated is stainless steel. Moreover, the type of stainless steel utilized, S303 or S304, is directly connected to the nozzle’s model and the processes in which they are implemented. Regarding the SLNHA-H series, the product is manufactured either from S304 or from PVC. Each material is suited to fit a certain type of application and satisfy your requirements. Choosing the adequate material should be considered following the given parameters:

- Application temperature.

- Possibility of mechanical or chemical aggressions.

- Environments with hygienic requirements.

- Need for absence of metallic elements.

Being designed by Ikeuchi, the compressed air nozzles have been engineered with the major scope that they deliver the expected quality that you, our customer, expect to receive. For some models, the quality that they provide is attributed to the fact that the products are efficient in minimizing the loss of pressure, and by doing so it improves the blowing impact while reducing the air consumption. Their implementation and use in large quantities are assisting in cost reduction. While for others, quality relates to precise adjustment of the volume of air, efficiency, and reduction in the utilization of the supplied air, providing a lower noise level and are easy to maintain.

To comply with the OSHA noise level requirements and regulations, Ikeuchi designed and tested its compressed air-driven nozzles to make sure of the level of noise produced. By doing so, the compressed air driven nozzles provide a reduction in noise between -9 dB(A) and -38 dB(A) from the overall total noise level, thus, abiding by the OSHA noise regulations of 8 hours workday exposure to noise levels below the average 85 dB(A).

Are you interested in discovering more information regarding our compressed air nozzles and characteristics? On each product page you can find the technical information over a nozzle’s:

- weight,

- material,

- noise level,

- recommended operating pressure,

- and air consumption.

Besides, this information can also be encountered within the individual product catalog sheet or each nozzle, alongside with an in-depth technical overview. All you must do is download the document. You can also download the general product catalog and review the model drawings in 2D or 3D. We made it easy and accessible for your experience. However, for any question or query, you can always contact our specialists and they can advise you and provide you with their know-how.

At IKEUCHI, we have determined the fundamentals to select the right nozzle for your application based on their characteristics. When selecting the nozzle, we advise you based on your required spray angle, spray capacity, optimum spray pattern, and spray distribution.

If you have technical question about nozzles, need advice to choose, or request a quote,