The partnership with our distributor for the Baltic countries started more than 10 years ago with Kaupo Juhandi as the person in charge. Initially, Kaupo Juhandi was appointed as a distributor for several process equipment, including Ikeuchi spraying equipment.

In 2019, Kaupo Juhandi established TÖÖSTUSPUMBAD OÜ in Estonia, near Tallinn. Customers responded positively to this new-established dynamic and reliable pump supply company, and since then the partnership with Ikeuchi got stronger as well. The company’s vision is to improve efficiency in production processes by using the right industrial pumps, nozzles and tank cleaning applications.

What kind of products do you sell?

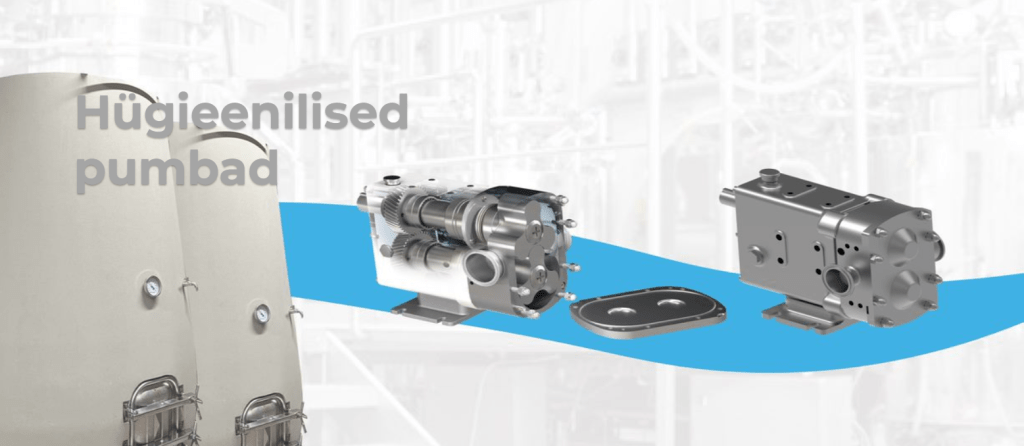

TÖÖSTUSPUMBAD’s mission is, to supply best-in-class pumping solutions, nozzles and tank cleaning

and humidification applications to the food, beverage, pharmaceutical, home care, wood and other

manufacturing sectors in Estonia, Latvia and Lithuania.

The pump types are rotary lobe pumps, peristaltic pumps, centrifugal pumps, diaphragm pumps,

drum pumps for all viscosities – drum unloaders; IBC pumps, circumferential piston pumps,

progressive cavity and twin screw pumps.

Ikeuchi delivers us nozzles, other spraying solutions for moistening, tank cleaning, wetting,

humidifying or for cleaning. Humidity control for different production units, besides cooling and

humidity in drying chambers.

What is your main market?

We are mainly doing projects in the wood industry, green house and the metal industry. For wood

industries we are an experienced partner in the field of wood drying. Our nozzles are widely used in kiln drying and drying chambers.

Since Estonia’s climate is around -15ºC from November to March, the manufacturing industry has many issues with ESD. In addition, the climate in June can be up to +30ºC and with a high moisture percentage, which makes cooling equipment attractive. We increasingly receive inquiries from the electronics industry and wood industry about nozzles and humidity control. It is even more prominent in winter time when ESD is quite common.

Are there any special projects you would like to mention?

A few years ago we had a very interesting project in a fishmeal and oil factory to find working solution for raw material reception tanks. As tanks are special, we sorted out the whole cleaning machine`s product range and characteristics to find a dynamic cleaning solution for customer. Usually, high-impact jets are equal with high efficiency cleaning, but their jet lengths and spray pattern were calculated very precisely according to the tank design. However, in this case, high-impact jets would have made the fish “fly” to unwanted places. In the end, we finalized the project with Ikeuchi’s RJ series tank cleaners, which was a success.

RJ tank cleaners

It is my absolute pleasure to have this partnership with Ikeuchi and to know that I can reach out at any time to receive support from the team in LR Breukelen.

Kaupo Juhandi

Founder, TÖÖSTUSPUMBAD OÜ