February 27, 2025

Spray nozzle cooling solutions in the steel industry

Cooling takes place during several steps of the steel making process. Ikeuchi provides premium quality spray nozzles and control systems, CFD simulation analysis and cooling trial experiements, combined with an outstanding performance record for the steel industry.

Slab cooling

For cooling of hot slabs, a strong impact force is needed. By directing a fine mist over the slab, the heat dissipation can be enhanced.

DOVEA spray nozzle setup for slab cooling

- DOVEA produces a large volume of semi-fine atomization with a mean droplet size of 50µm and more.

- Liquid pressure type under the liquid pressures of 0.07 – 0.7 MPa (ca. 0.7 bar – 7 bar).

- Large turn-down ratio with minimal variation in spray angle.

- Uniform distribution suitable for multiple-nozzle arrangements.

- Large free passage diameter minimizes clogging.

- Standard spray angle of 55°, 70°, 95°, or 110°.

- Find it here

Thin slab cooling

The cooling of thin slabs with spray nozzles requre a finer mist and more precision than thicker slabs. This is because thin slabs are more susceptible to thermal stresses and damage during rapid cooling than thicker ones.

BIM integrated header for thin slab cooling

- The BIM spray nozzle produces a fine atomization of 100µm or less.

- The BIM header integrates air and water pipes in one rectangular header.

- It provides a uniform spray distribution across the entire spray area which is suitable for thin slab cooling.

- The BIM header is compact and easy to maintain.

- Find it here

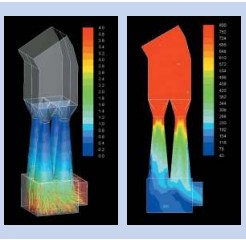

Flue gas cooling

Flue gas cooling can be neccessary during several stages of the steel making process and can effectively be done by spray nozzles. Ikeuchi uses CFD calculations to select the perfect control system and nozzles for the specific application.

GSIMII for flue gas cooling

The number of required nozzles can be reduced with GSIMII, which combines a large spray capacity with a fine fog of 50µm. This allows for a smaller gas cooling tower design than normally, reducing construction and maintenance costs.

Find it here

Do you want to know more about spray nozzle technology in the iron and steel industry? Download our iron and steel catalog: