February 12, 2024

How to choose an automatic tank cleaner

An automatic tank cleaner can save your business hours of manual cleaning and manpower as well as water and chemicals. At the same time, an automatic tank cleaner is more hygienic and efficient than a manual tank cleaning and it leaves the same result every time.

Different types of tank cleaners

Automatic tank cleaners can be divided into different categories depending on the spray pattern and the nozzle rotation

Spray pattern of automatic tank cleaners

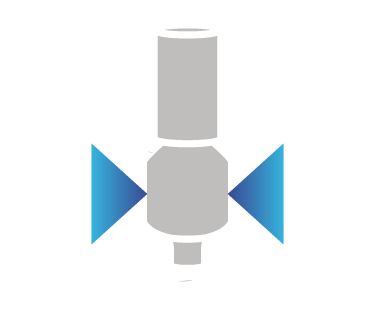

Solid stream pattern

This nozzle sprays the cleaning liquid in a straight single stream.

Use for: Clean hard to remove dirt and sticky spots

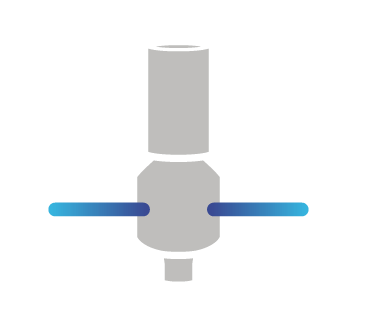

Flat spray pattern

This nozzle sprays the cleaning liquid in a flat fan shaped pattern.

Use for: Washing large surfaces quickly

Nozzle rotation of automatic tank cleaners

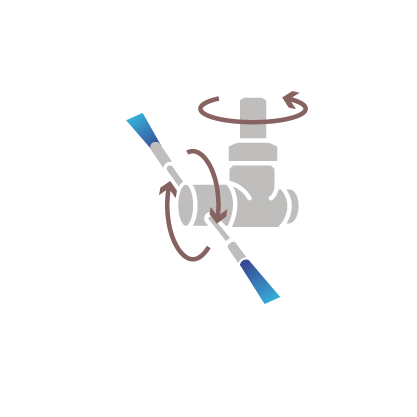

3D rotation

This nozzle uses two rotary drives, It can clean while rotating at 360 degrees.

Strong cleaning power.

2D rotation

This nozzle uses only one rotary drive. It can quickly clean a large area.

Medium cleaning power.

Fixed – no rotation

This nozzle has no rotary drive or moving parts that can fail or cause wear debris.

Easy cleaning power

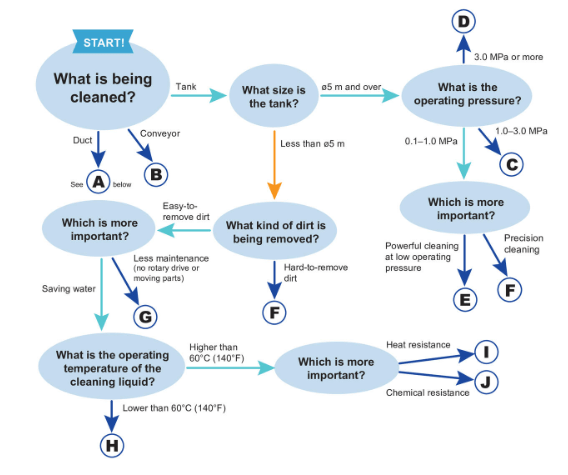

Nozzle selection guide

Find your ideal tank cleaner based on usage and cleaning objectives:

Pharmaceutical industry

A pharmaceutical company found it time consuming to clean medical tanks manually and also wanted to reduce the risks of accidents while increasing hygiene. They succesfully installed a 2D rotation tank cleaner from the ES series.

Food and beverage industry

A beer brewing company could spend a whole day on manually cleaning their yeast tanks. The brewery installed SWB series tank cleaning nozzles to their tanks. This agitated the residue while draining it and cleaning the tank at the same time.

Paper and pulp industry

A paper mill spent 30-40 minutes on cleaning a single raw material tanks manually. In order to save time and labor they installed the rotating cleaning nozzle RJ. This reduced the cleaning time by 20-25 minutes and allowed for cleaning of multiple tanks simultaneously.

Chemical industry

A spray dryer manufacturer was using a high-pressure rotating tank cleaner nozzle to clean their ducts, cyclones and powder tanks after spray drying. However, the wind blowing through the ducts was affecting the spray, which resulted in uneven cleaning. Instead, they succesfully installed the RJ2-PON which was designed for duct cleaning, and reduced cleaning time by 1.2 times.