January 27, 2025

How to choose an air nozzle?

There are many factors to consider when you have to choose an air nozzle. These include:

- Application

- Air pressure and air volume

- Material

- Spray pattern

- Noise level

- Energy efficiency

- Cost

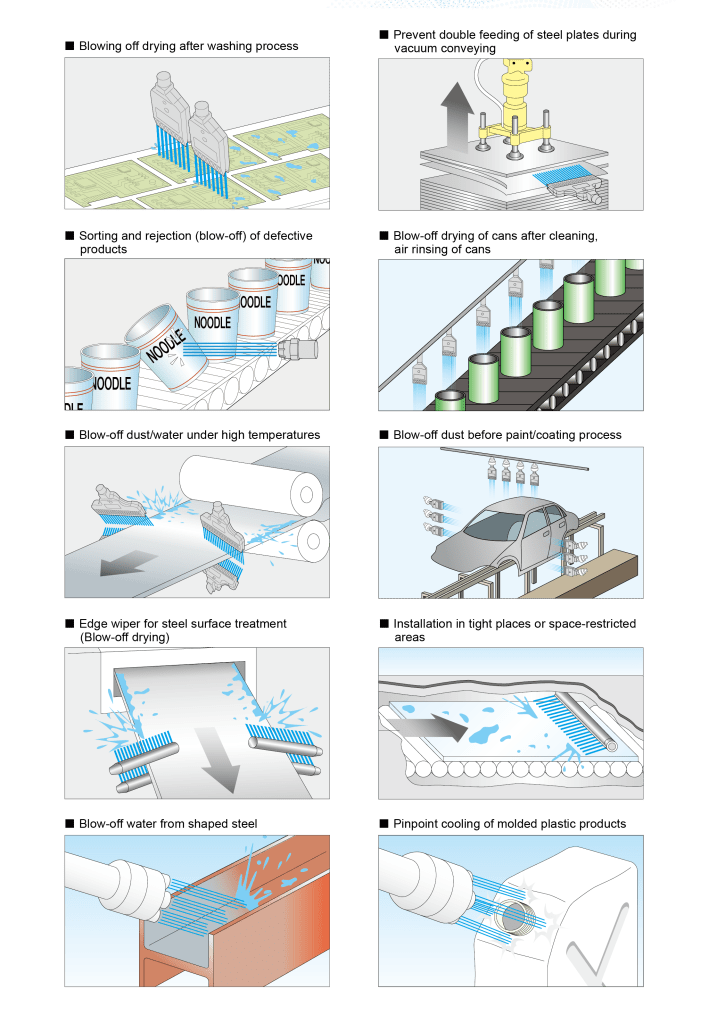

1. Application

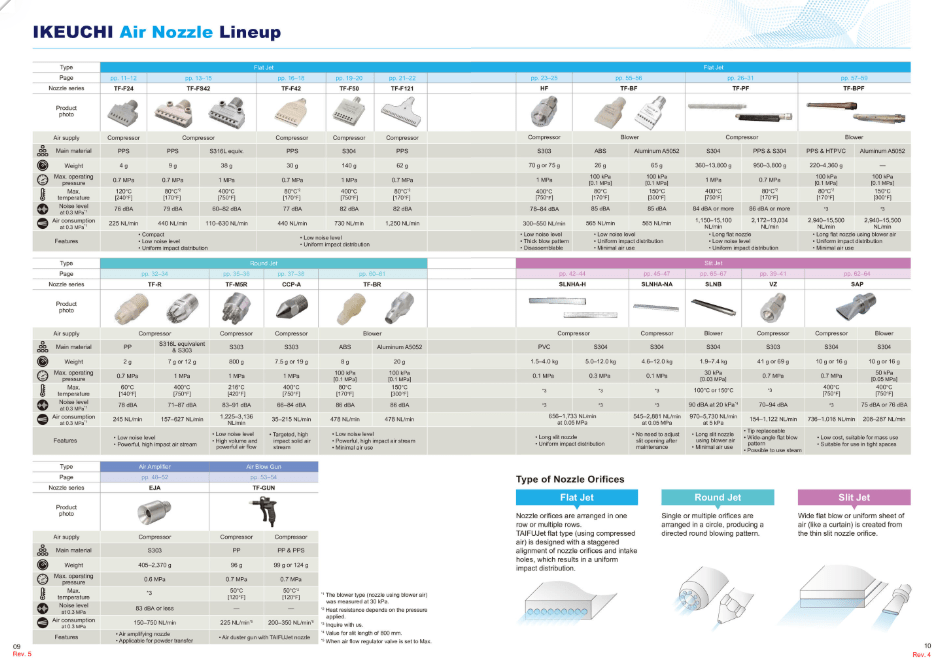

Air nozzles can be used for a number of applications and industries. When you have to choose an air nozzle, it is important to consider the application first. We divide our air nozzles into two categories: compressed air driven nozzles and air blower driven nozzles. These categories represent each way that the air can be supplied to the nozzle and they can be used for different installations. Each of them has unique properties and will answer better to one kind of application.

Compresser-driven >< Blower-driven air nozzles

Generally, blower-driven air nozzles are used in applications where the air need to be constant, such as with cooling and blowing off water. Compressed air driven nozzles are more suitable for applications where the air blow is more intermittent as the compressor need to maintain a high pressure, such as with sorting and rejection or vacuum conveying.

2. Air pressure and air volume

Air pressure and volume is also important to consider when you have to choose an air nozzle. The required air volume depends on a number of things including the surface area, the distance from the air nozzle to the surface area and the application. Moving larger objects will naturally require a higher air pressure and volume than moving smaller objects.

Surface area: A large surface area requires more air to be covered effectivily and maybe also a broader type of air nozzle.

Distance: The air pressure and volume is also affected by the distance it needs to travel from the air nozzle to the surface area. The longer the distance, the higher the needed air volume. Compact air nozzles which can fit into narrow areas will help to reduce energy waste due to distance.

Application: Generally, an application like food sealing will only need a small air volume around 10-20CFM, whereas cooling requires a bit higher air volume around 50-100CFM. Blowing off water generally requires an even higher volume above 100CFM depending on the amount.

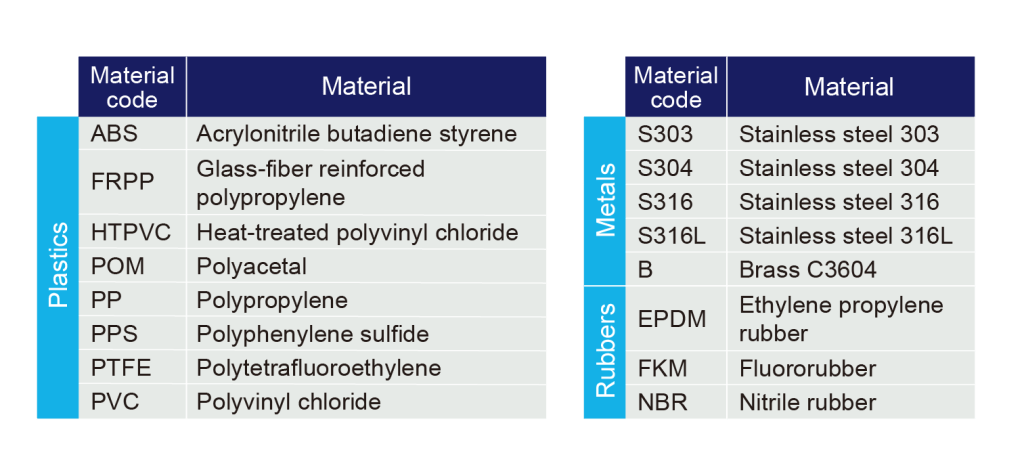

3. Material

Air nozzles can be found in different materials ranging from stainless steel to various types of plastic and aluminum. Plastic nozzles are generally cheaper, lightweight and resistant to many chemicals, than metal alternatives. For high-pressure and high-temperature applications, stainless steel and aluminum is a better fit. Below you can see an overview of the different air nozzle materials.

4. Spray pattern

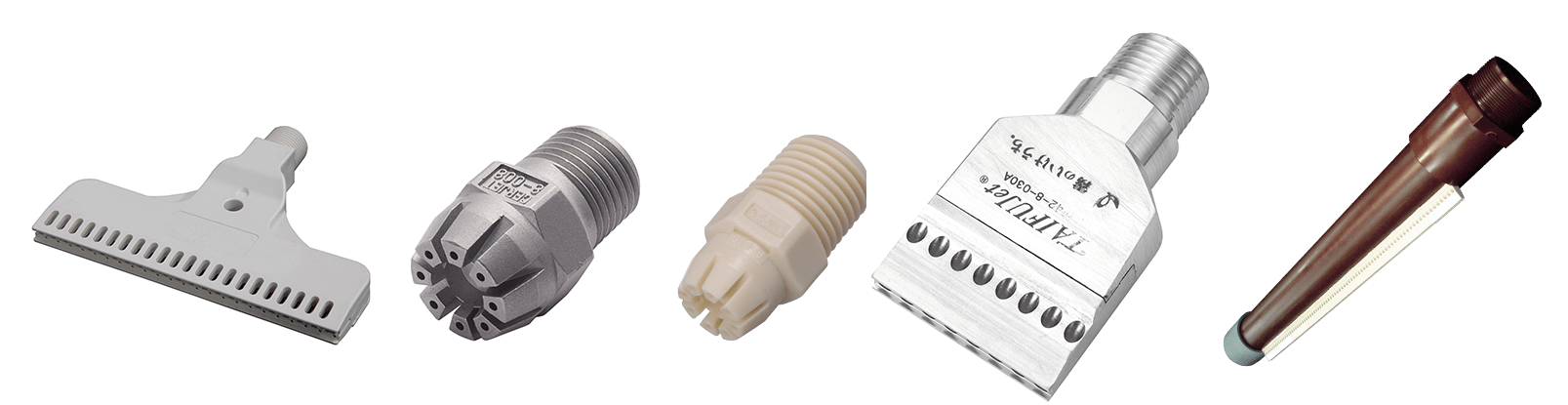

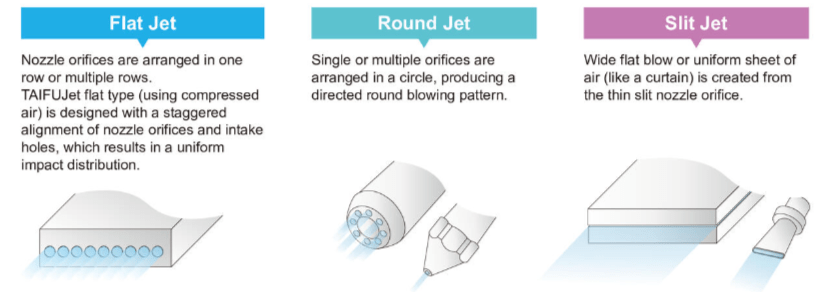

Air nozzles also differ in their spray patterns. Some blow in a fan shape, some with a round shape and others with a more long and thin spray, like blades. Depending on the area of treatment, the sizes of the nozzle will influence the choice of the model.

- A flat fan shape spray (like our TF-BF42 nozzle) has a larger opening for a high impact of air stream at low noise level.

- A round jet air booster, (like our TF-BR series) is designed with six orifices to generate a powerful high impact air stream while saving energy and generating low noise level.

- For a longer flat spray distribution that can cover a single area up to a 1,596 mm of width, slit nozzles (like our TF-BPF and SLNB series) are more suitable, especially in confined spaces.

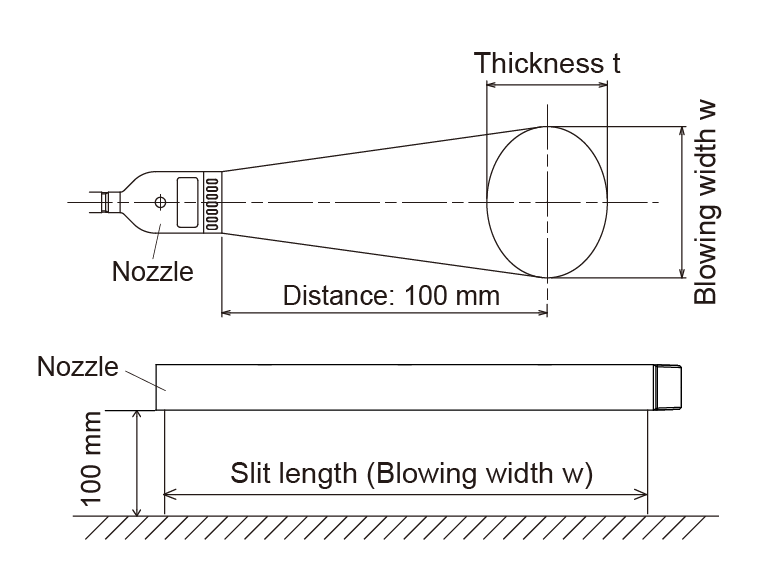

Blowing air spread is measured 100 mm from the air nozzle orifice. The blowing width can be used as a guide for spacing nozzles. The shape of the blow pattern is generally closer to a circle as the distance from the nozzle decreases.

5. Noise level

Noise from compresser-driven air nozzles can cause unneccesary stress and discomfort with employees. The accepted noise level of your air nozzles depends on the working facility and the presence of employees. By using air nozzles which operate more quietly, the sound pressure can be reduced by as much as 80% without losing performance.

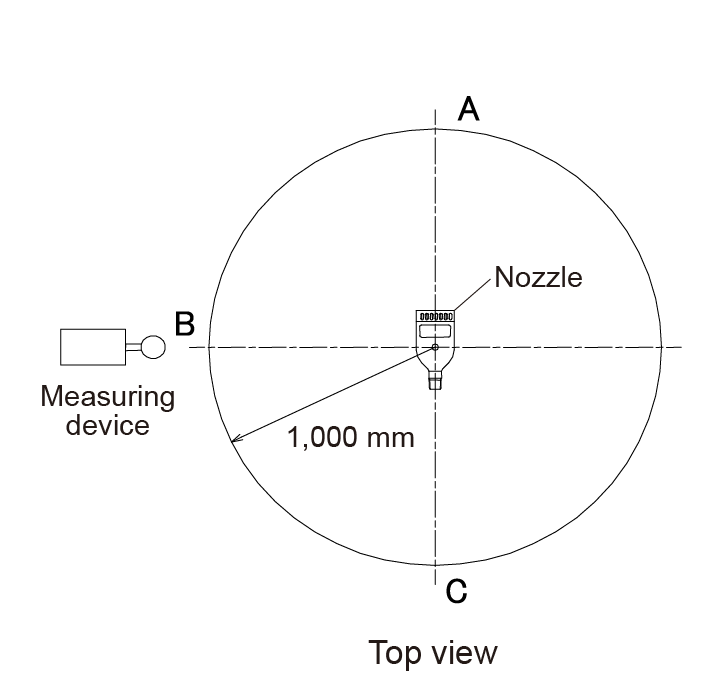

Noise levels can generally be measured at 3 points A, B and C at a distance of 1,000 mm from the nozzle. The nozzle is installed at a height of 1,000 mm.

6. Energy efficiency

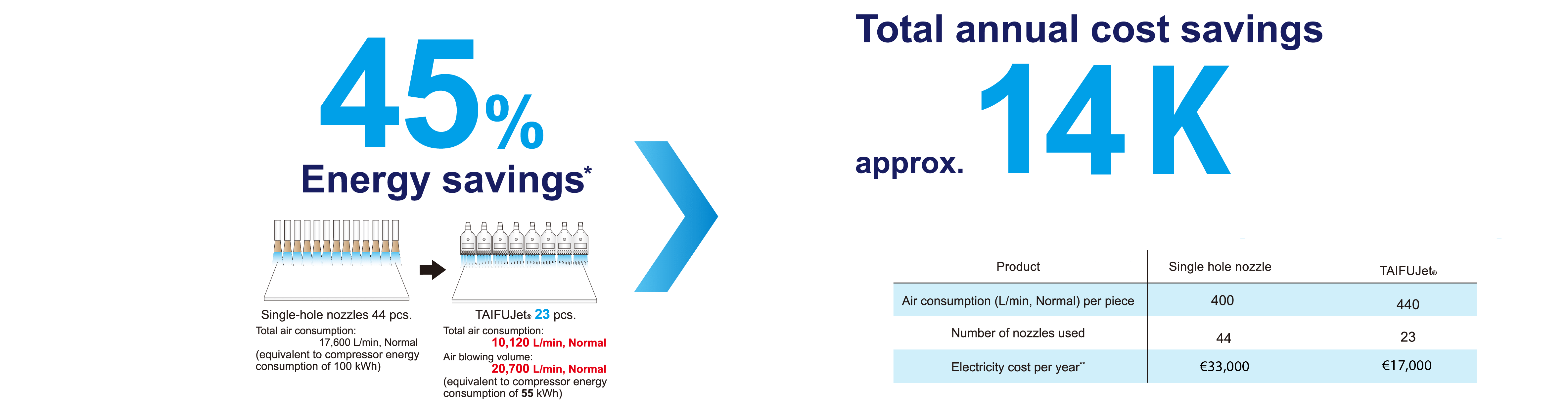

Air nozzles come with a great difference in energy efficiency. To increase the blow effect of the air nozzles, and thereby the energy efficiency, it is important to provide a uniform air stream impact. This will create an even distribution of air across the target area and less power will be needed. This is why we often recommend multi-hole air nozzles compared to single-hole nozzles. An energy saving of 45% can be achived by switching from one-hole to multiple ones, like TAIFUJet®.

7. Cost

The price of air nozzles should always be seen in the light of efficiency and wear resistance. If the air nozzle quickly deteriorates or a larger amount is needed to fulfill the task, the cheapest air nozzle may not be the cheapest in the end. We often recommend to test a few air nozzles before making the final decision to reach the best and most cost-efficient result.

Now you are ready to select the appropriate air nozzle for your application.

Download our air nozzle catalog to find the line-up of our air nozzles or find our air nozzles here.

Still in doubt about which air nozzle to choose? Contact us for free advise from one of our experts.