October 3, 2024

How to choose a spray nozzle

In order to choose the correct spray nozzle it is important to understand how they differ from each other. The wrong choice of spray nozzle can lead to overly water and chemical use or accelerated nozzle wear.

These 5 specs are important when selecting a spray nozzle:

- Spray angle

- Spray capacity

- Spray pattern

- Spray distribution

- Spray nozzle material

Spray angle

The spray angle is the angle of spray from the center of the nozzle. As the spray flies through the air, droplets gradually lose momentum and the area it can cover decreases.

In actual spraying, the spray width varies with spray height. Take this into consideration when designing a nozzle layout.

Spray capacity

The spray capacity becomes larger as the liquid density becomes lower, and the liquid pressure becomes higher.

The spray capacity is inversely proportional to the square root of liquid density. To determine the spray capacity of liquid having density (γ), multiply the spray capacity shown in our catalog by conversion factor of .

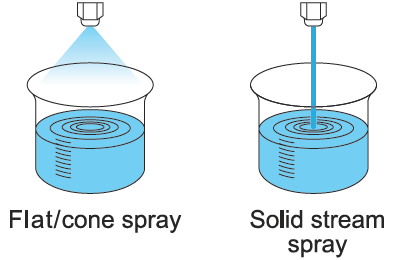

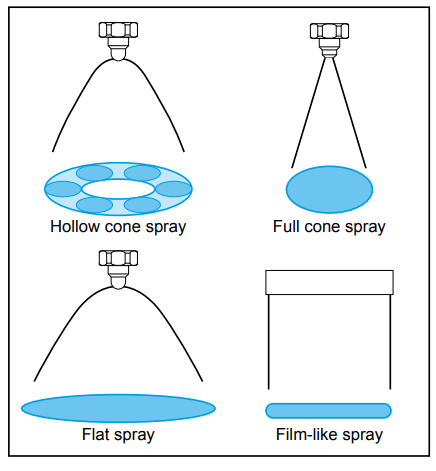

Spray pattern

The spray pattern means the cross sectional shape of the spray. They can be categorized in 4 different shapes:

- Solid Stream Jet

- Flat Spray

- Hollow Cone Spray

- Full Cone Spray

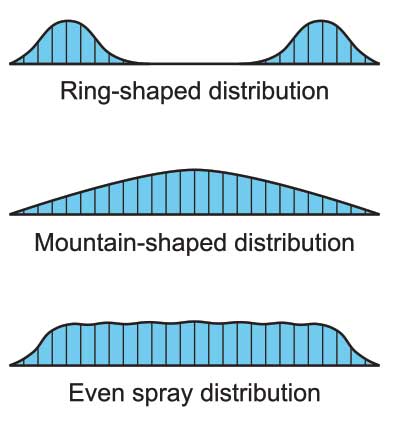

Spray distribution

The spray distribution means the distribution of spray flow in the spray width direction.

A mountain-shaped distribution facilitates producing uniform spray distribution across the entire spray width by overlapping patterns in multiple-nozzle arrangements, while an even spray distribution is suitable for applications like cleaning that require uniform spray impact across the entire spray width.

Spray distribution varies depending on the spray height and pressure.

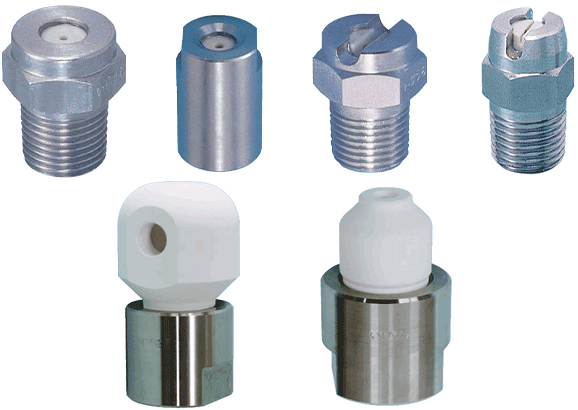

Spray nozzle material

It is important to consider the purpose of the spray nozzle when choosing the material. Some materials are more resistant to chemicals or high temperatures than others. The choice of nozzle material can have a significant impact on the efficiency and the lifespan of your nozzle.

The types of materials used:

- Stainless steel

- Die-cast stainless steel

- Hardened stainless steel

- Brass

- Plastics

- Ceramics

- Aluminum

Read more about spray nozzle materials here