Problems with dripping

Dripping spray nozzles are not only bad for water conservation and the water bill, it is also a nuisance for your surrounding equipment and employee safety. If you struggle with dripping spray nozzles, use our short guide to end it today.

Issues caused by dripping spray nozzles:

- Excessive water use

- Employee safety issues

- Wet floors

- Higher costs

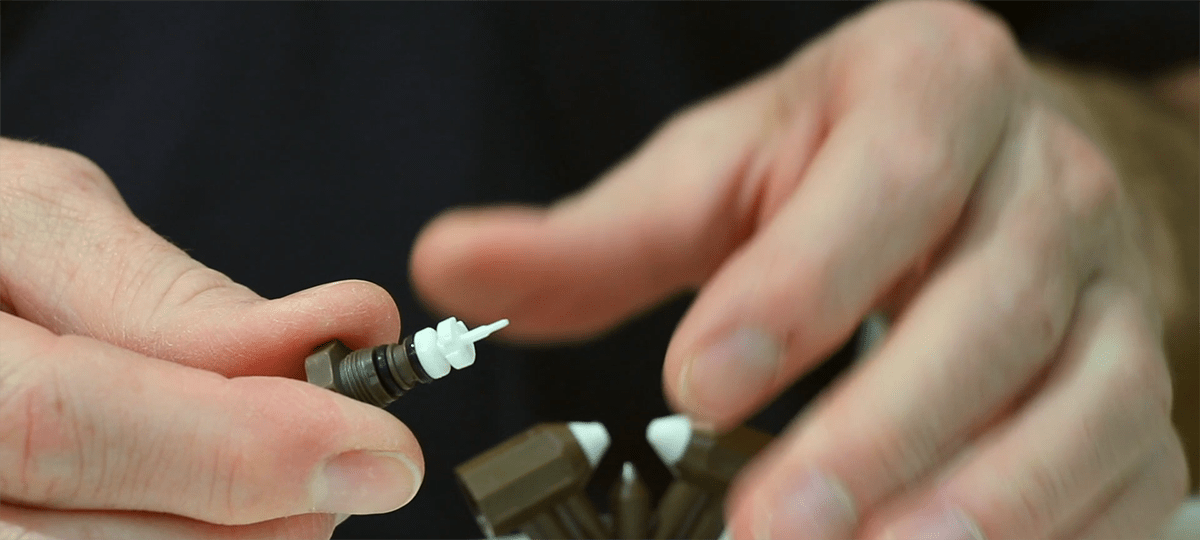

Applying a check-valve

By applying an in-line check valve between the piping and the nozzle, dripping can be eliminated completely. In addition, the check-valve enables a more responsive spray-start by filling liquid up to just before the nozzle. Watch the movie below to further understand how it works (English subtitles are available).

How does the check-valve work?

A check-valve is designed to only allow water to flow in one direction. The check-valve will open at a minimum pressure and reseal again once the pressure wears off. The check valve works due to a spring-design. The spring creates a force that pushes the valve into a closed position, preventing water from passing through. Once the system is turned on again and the pressure exceeds the spring’s resistance, it pushes the valve open, allowing water to flow through the nozzle and spray out.

Is my spray nozzle dripping because it’s damaged?

Before you invest in a check-valve it might be considerable to check whether your spray nozzle is worn out and needs replacement. A damaged orifice with a bent shape could also cause dripping. In addition, if the spray pattern has changed due to nozzle wear, the jet may hit the nozzle body and cause dripping. You can read more about how to detect spray nozzle failures:

Related articles

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”