July 28, 2023

Gas turbine cooling

With the ongoing global climate concerns, energy conservation has become more important than ever. In addition, temperatures are higher than ever measured before and very likely to increase further in the future. With this in mind, Ikeuchi has developed a cooling system which can improve the efficiency of gas turbine power plants significantly during high temperatures. With this solution, an enormous amount of electricity can be saved and the stability of gas turbine power plants can be ensured.

Why does a gas turbine need coooling?

In order to generate electricity, a gas turbine heats up a mixture of fuel and air at extremely high temperatures, which causes the turbine blades to spin. When the turbine spins, it drives a generator which converts the energy into electricity.

During summertime, the high temperatures cause the air to expand and decrease in density, resulting in a reduction in the mass flow of the inlet air drawn into the turbine. Consequently, the volume of injected fuel will also decrease and thereby the overall power output of the gas turbine will decline.

How does it work?

If the inlet air can be cooled before entering the gas turbine, the power output of the gas turbine can be increased.

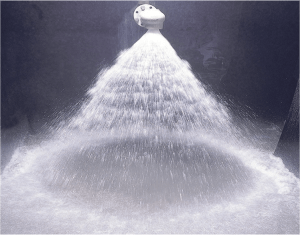

Ikeuchi’s cooling solution consists of a wall of spray nozzles which produce a semi-fine dry fog. These uniformly-sized droplets are so small (10 to 30μm) that they will instantly evaporate upon spraying, effectively cooling the inlet air.

This method achieves effective cooling with a minimum water consumption, eliminating excess water and preventing the interior of the inlet air duct from getting wet.

Results

The system is capable of reducing the inlet air temperature by approximately two to four degrees ºC in Japan.

In countries where there is a combination of high-temperature and low-humidity climates, the reduction can be even more significant, reaching 15 to 20 degrees C.

It is generally observed that for every one-degree Celsius decrease in the inlet air, the power output increases by approximately 0.6 to 0.8%.

Other sustainable solutions from Ikeuchi

Dust suppression for environmental protection

- Pneumatic spray nozzles are capable of dust suppression without significantly wetting the environment

- Dust content can be reduced by more than 90%

- Reduced amount of pollution getting into the environment and safer working environment. Read more here

NOx reduction

- Spray nozzle / injection lance for NOx reduction to purify the air through a catalytic reduction.

- Ikeuchi’s solution is more sustainable due to its extended lifespan and protective equipment

- Energy saving due to low air consumption

- Read more here

SOx reduction

- Desulfurization plants need to follow industrial requirements to clean their exhaust gas before releasing in the environment.

- In order to offer a long life-time nozzle, IKEUCHI uses SiC and SiSiC material for Wet FGD spray nozzles

- Read more here