November 23, 2023

Beer brewing solutions

Craft beer breweries have been struggling the past years following the covid-crisis, a steep rise in production costs and a new generation which care less for the golden drink. Small beer breweries can only survive now if they implement some strict measures to increase the efficiency and lower their costs. Ikeuchi has several solutions which can help beer brewers to increase efficiency.

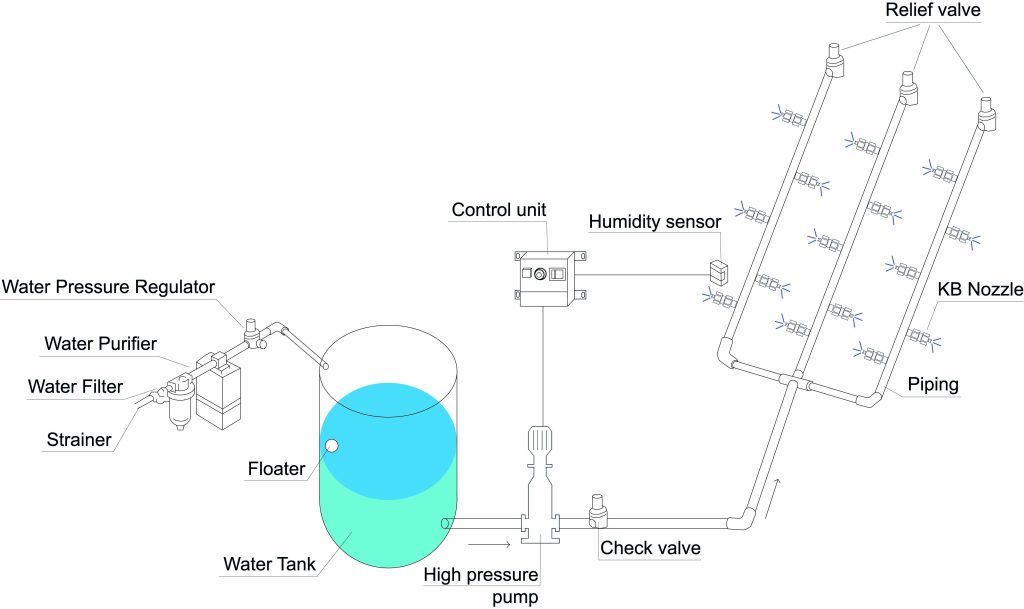

Adiabatic Cooling System for Germination Process

Barley needs the ideal growing conditions during the germination process. This means a temperature around 15-20 degrees and constant humidity. Under these conditions, the barley not only germinates faster and more homogenious, but it is also a more energy efficient process. By applying adiabatic cooling in the Ventilation Chamber before the Germination Kiln you can ensure a constant humidity level.

Our KB humidification system

- The KB humidification system consist of hydraulic spray nozzles with the finest atomization among hydraulic nozzles (45 – 210 μm).

- The whirl chamber is formed by a ceramic orifice and closer, which provides excellent wear resistance.

- A cost and energy efficient solution.

Benefits of KB nozzle in the Germination Process:

• A faster germination process meaning reduction in cost, higher production = Increased revenue for Brewing industry.

• Since it is non-wetting = no spoiling of grains

• Homogeneous humidification maintains a better and more even flavor in all batches.

• Less water consumption, which decreases costs of grain germination process.

Yeast tank cleaner

With an automatic brewing tank cleaner, one can save an enormous amount of time and costs on manual labour. A client of Ikeuchi was wasting too much time on draining residues from the yeast tank and cleaning the tank inside after use. Since water had to be sprayed to dilute the highly viscious residue, draining it afterwards took a lot of time. Cleaning multiple tanks could cost the brewery a whole day!

The solution:

Ikeuchi suggested a shower ball cleaning nozzle attached to the tank lid and using it like a shower. This agitated the residue while draining and cleaning the tank at the same time. Automating the cleaning of the tanks eliminated the need for manual labour.

SWB-series tank cleaner

The SWB-series has a simple and cost-efficient structure. Since it does not have any rotating or moving parts, it is less sensitive and requires less maintenance.

Due to its shower head function with multiple holes, this tank cleaner will reach all corners of a brewing tank (see the movie below).

Download our tank cleaner catalog here

Find the SWB here

Cleaning of fermentation tank

A client of Ikeuchi experienced that their fixed tank cleaner left some uncleaned spots when cleaning the fermentation tank.

Solution:

Ikeuchi suggested implementing a rotary jetter nozzle. Our client was very satisfied with the solution and was able to reduce their automated cleaning process by 10 minutes as well.

The ROTARY JETTER RJ series tank cleaner’s features:

- Solid stream jet provides high cleaning performance

- 360° rotation thoroughly cleans inside of a tank.

- 2-nozzle and 4-nozzle types are available.

- Compact design allows for installation in a tank with a small inlet.

- Find the Rotary Jetter here

Bottle cleaner

The rinsing of bottles and cans before filling them is an important measure to avoid any hygiene incidents and to increase the shelf life. Furthermore, the recycling of bottles can be an easy way to save costs for smaller breweries.

7 stream cleaner

The 7-CP-series is a strong bottle cleaner with seven solid streams with a high impact force. The spray nozzle has a compact design and is an easy and cost-efficient bottle cleaner to implement.

Find the 7 stream cleaner here

Bottle label

Adding a fine mist to your bottle lable process can ensure that it sticks properly and avoid wrinkles, bubbles, or smear. Our BIM spray nozzles are suitable for this application due to its fine atomization with a mean droplet diameter of 100 μm or less.

Find our BIM spray nozzle here