June 20, 2024

A greener humidification solution against ESD

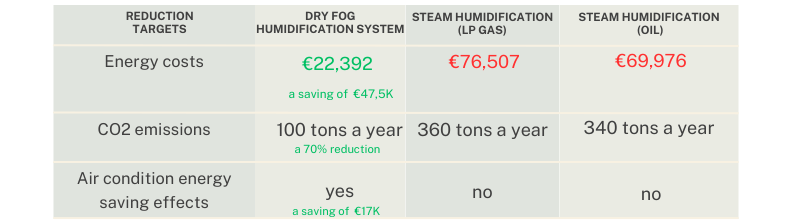

It is long known that an efficient humidification system is crucial to combat static charge (ESD) issues in electronic productions and SMT. Traditionally, steam humidification has been used to prevent this issue. However, with the increasing energy prices and environmental concerns, steam humidification is no longer the optimal choice for this. By switching from your current steam humidification system to an adiabatic system, such as AKIMist®, you can save more than €60K per year in energy costs (see below). This makes it possible to earn back your sustainable investment in just 2 years.

How can a dry fog humidification system be so energy efficient?

One of the most important differences between steam humidification and a dry fog humidification system is that a steam system cannot shut down in between. This means that a lot of energy goes to waste. A dry fog system, on the other hand, can automatically turn on and off whenever the humidity level drops below the limit. This means that a 100% goes into the factory and nothing is lost.

Energy savings on air-conditioning

Most electronic facilities have air-conditioning due to the heating caused by equipment. For steam humidifiers, air-conditioning works against their purpose and they will need to produce even more steam in order to maintain the wanted humidity level. The dry fog system works together with the air-conditioner and has a cooling effect. It can reduce 20% of the air cooling energy needed for the air-conditioning.

Dust suppression advantage

Another advantage of a dry fog humidification system is its dust suppression ability. Since the dry fog is sprayed inside the facility, it can suppress dust while controlling the humidity level. There are two reasons why dry fog can suppress dust. First of all, due to the humidity increase, the conductivity of the air is also increased. This prevents dust from sticking to objects due to an electrostatic charge. Secondly, due to the dry fog droplets which are as small as dust particles (below 7.5µm) these droplets can suppress the dust particles.

The best choice for quality and energy-efficiency

The dry fog AKIMist® humidifier, is a unique Japanese invention which offers full control of the humidity levels in a factory. It is an adiabatic humidifier, which means that it increases humidity by adding cold water to the air. AKIMist is known for its non-wetting abilities as the droplet size is less than 7.5μm. This means that the droplets are so small that they will bounce back without bursting on any surface. No risk of leakage or condensation. This is a very convenient ability in a factory with expensive machinery and materials which cannot get exposed to water or condense.

Advantages of AKIMist dry fog humidification system

- 80% less energy use

- Cooling effect for reflow

- Dust suppression

- Non-wetting

- Low maintenance

- Easy to install

- Read more about AKIMist here