Printing

Humidification for Sheet-fed offset printing

Process

Issues in Sheet-fed offset printing

- Double feeding

- Misalignment

- ‘Offset Double’

- Paper curling

- Poor stacking

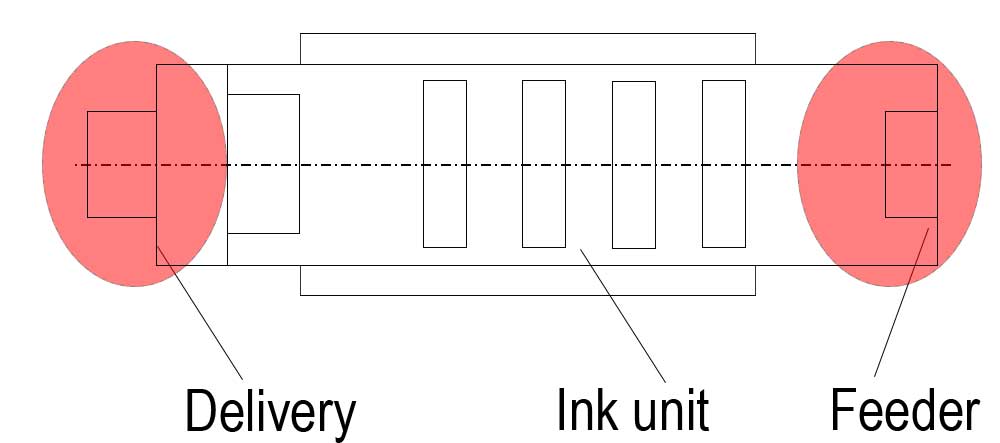

Offset sheet-fed printing machine drawing

Solution: Humidification for Sheet-fed offset printing

A low humidity level affects printing facilities by increasing defect rates and shutdowns of machinery. Static electricity increases, especially during winter time, creating poor quality of products, misalignment, paper jams, double feeding, dust adhesion, and even fire.

By adding spot humidification near the machinery, these problems can be prevented, static charge is controlled, and our customers can maintain a constant level of quality in their production year-round.

High speed sheet-fed printing machines use UV which lower the humidity in the environment. Thus, it results in more static discharge due to the heat the machines generate. To operate these machines with higher speed, humidity control is essential.

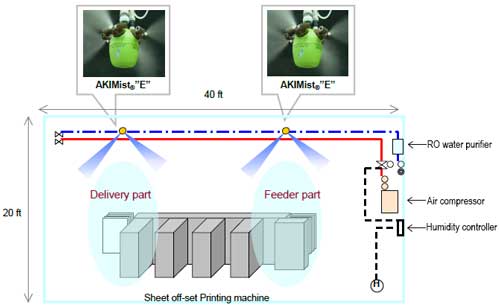

Our humidification system sprays a “Dry Fog” which will humidify in high speed near the machines without wetting them.

Example of Systems / Products used for this solution

Solutions

Benefits

- Reduced press stoppages and paper jamming (due to double feeding)

- Increase in production speed

- Reduced paper curling

- Improved product quality

Advantages of the solution

- Anti-static measures for target areas

- Cost saving (lower defect rate, decrease in operational shutdowns)

- Constant humidity level year-round (50-60%RH – depending on customers’ needs)

Example of an installation of the AirAKI® system with the Dry Fog humidifier AKIMist®”E” above a sheet off-set printing machine

Applications

- Focus humidification for Sheet-fed offset printing at the feeder and delivery

- Humidification at ink unit part in case of larger machines with 8 colors or more

- Prevention of static charge

- Other applications: humidification, indoor cooling