September 28, 2023

Cheese ripening and humidity

Cheese ripening and humidity control

Humidity control is critical in the cheese ripening process. Proper humidity control is essential for achieving the desired texture, flavor, and quality of the cheese. Here’s an overview of how cheese ripening and humidity control are interrelated:

Why is humidity control important for the ripening process?

- Most cheese need a high level of consistent humidity in order to develop the optimal flavour, aroma and texture.

- During the curing process, the cheese undergo various biochemical changes which can be greatly influenced by the humidity level.

- The ideal humidity level for cheese curing can vary depending on the type of cheese, but it generally falls within the range of 80% to 95% relative humidity (RH).

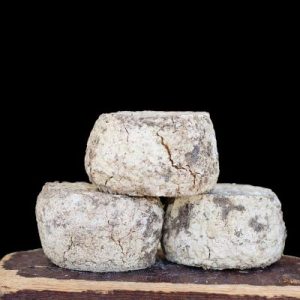

Humidity control and the molding process

- Originally stored in caves, the curing environment for mold cheeses is very important

- Humidity and temperature control is important in order to prevent unhealthy mold processes.

- Mold cheeses generally need a high humidity in the range between 85-92%

- Washed-rind cheeses, may require special surface treatments like brine washing or mold inoculation, which can also influence humidity levels and the development of specific flavors.

Hard versus soft cheese

- Soft cheeses like Brie and Camembert generally require higher humidity levels to maintain their creamy texture.

- Hard cheeses like Cheddar or Parmesan may need lower humidity to develop their characteristic firmness and flavor.

Humidity control with AKIMist® “E”

- AKIMist “E” sprays a “dry fog”. The droplets are so small ( 7.5 μm). that they bounce back without wetting any surface.

- The AKIMist “E” can spray the dry mist over a distance of 4 meters from each nozzle and can cover a large area with a single unit.

- By installing AKIMist “E”, the cheese curing process can be controlled.

- Learn more about AKIMist here

- Book a free demo of AKIMist here