Maritime

Dust suppression on ships during loading

Process

Dust suppression on ships

Dust suppression on ships during loading and unloading is important in the cases where the material creates a great amount of dust, like with grain or wood chips. If not controlled, dust can become a health hazard for workers, pollute the environment and destroy expensive machinery onboard the ship.

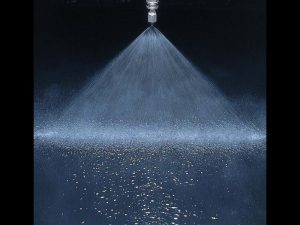

Control and suppress dust on ships with spray nozzles

Ikeuchi’s dust suppression spray nozzles will significantly reduce the dust onboard the ship during loading and unloading. We have numerous proven track records of dust suppression on ships, in factories and in production.

Solutions

Our spray nozzle Solution: BBXP

The BBXP series nozzles’ features:

- Full cone spray pattern with a round impact area and uniform distribution.

- Spray angle of 120° provides larger spray coverage than other nozzles.

- Spray capacity ranges from small to medium.

- X-shaped whirler provides large free passage diameter for minimal clogging.

The BBXP series nozzles have multiple applications:

- Cleaning:Gas, incinerator fumes, machinery, eliminators, screen, tanks, parts, crushed stones, earth and sand

- Cooling: Gas, machineries, tanks, steel plates

- Spraying:

Water treatment, aeration, foam breaking, fire extinguishing, dust suppression, sea water desalination

Our spray nozzle Solution: VEP

The VEP series nozzles’ features:

- Flat spray pattern with uniform distribution throughout pattern area.

- Even spray impact across the entire spray area.

The VEP series nozzles have multiple applications:

- Cleaning: Automotive, containers, films, felts, filters, screens, bottles, crushed stones, earth and sand, metal parts, machines, steel plates and pieces

- Spraying: Etchants, oils, lubricants, glues, solutions, insecticides, herbicides

- Cooling: Gas, smokes, heat exchangers, tanks, steels, roofs

- Water screen: Fire protection, heat protection, dust suppression, deodorization

Read more about the importance of dust suppression here: Dust suppression

Read more about the prevention of dust adhesion here: Dust adhesion