Printing

Humidification system in Web offset rotary printing

Process

Issues in Web offset rotary printing

- Press stoppages due to roll mis-feeding

- Paper jams in conveyors

- Paper dryness

- Paper folding (mis-folding)

- Static electricity

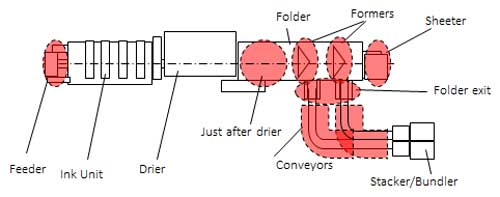

Web offset rotary printing machine drawing

Solution: Humidification system

A low humidity level affects printing facilities by increasing defect rates and shutdowns of machinery. Static electricity increases, especially during winter time, creating poor quality of products, misalignment, paper jams, double feeding, dust adhesion, and even fire.

By adding spot humidification near the machinery, these problems can be prevented, static charge is controlled, and our customers can maintain a constant level of quality in their production year-round.

Our humidification system sprays a “Dry Fog” which will humidify near the machines without wetting them.

Example of Systems / Products used for this solution

Solutions

Benefits

- Machine stoppages reduced to a tenth

- Increased press speed

- Reduced paper jams

- Reduction in waste paper

- Improved folding accuracy

- Increased productivity by 10%

Advantages of our humidification system

- Anti-static measures for target areas

- Cost saving (lower defect rate (decrease in operational shutdowns)

- Constant humidity level year-round (50-60%RH – depending on customers’ needs)

AirAKI® system with the Dry Fog humidifier AKIMist®”E”

Applications

- Occasional humidification near conveyors, folders, formers, feeder, rolling mill and just after the dryer

- Static charge control in the printing room and in the paper storage room

- Other applications: humidification, internal cooling