Pollution Control

FGD solutions for SOx reduction

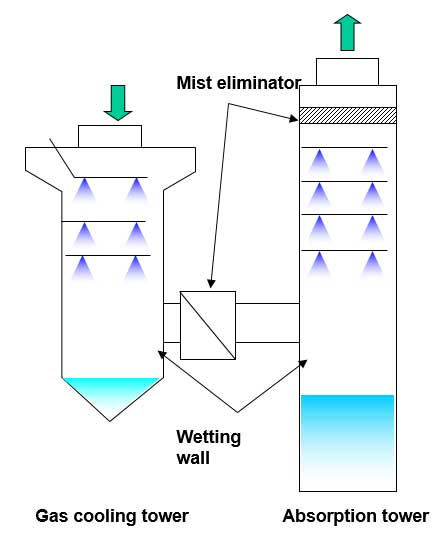

Process

Common issues for Wet and Semi Dry Flue-gas desulfurization (FGD)

- Desulfurization plants need to follow industrial requirements to clean their exhaust gas before releasing in the environment. SOx reduction requires atomization with slurry limestone in fine droplets.

- The difficulty of the slurry texture for a nozzle shorten its life-time, scrubbing inside the nozzle.

- And in order to achieve smaller droplet size, more rotation is needed inside the nozzle to break the droplets. Which increase the impact of the slurry limestone against the nozzle, thus, scrubbing its inside.

Desulfurization plant

Solution: SiC / SiSiC spray nozzles for Wet FGD and specialized nozzles for Semi Dry FGD

In order to offer a long life-time nozzle, IKEUCHI uses SiC and SiSiC material for Wet FGD spray nozzles. The large free passage diameter of the nozzles, of about 2.2 – 2.8 times larger than X shape whirler full cone nozzles, minimizes the clogging and creates smaller droplets.

For Semi Dry FGD, IKEUCHI manufacture nozzles with smaller droplet size and strong wear resistance to heat by using Alumina tip (AL99).

Example of Systems / Products used for this solution

- Wet FGD solutions:

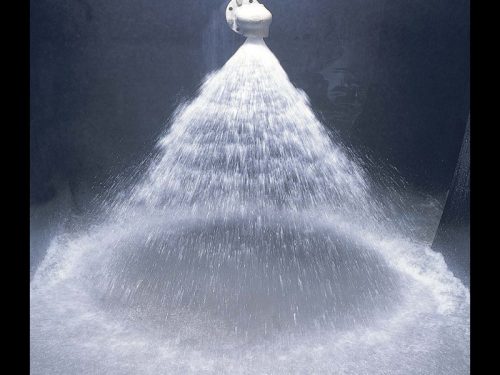

TAA series Large Capacity, Hollow cone spray nozzles

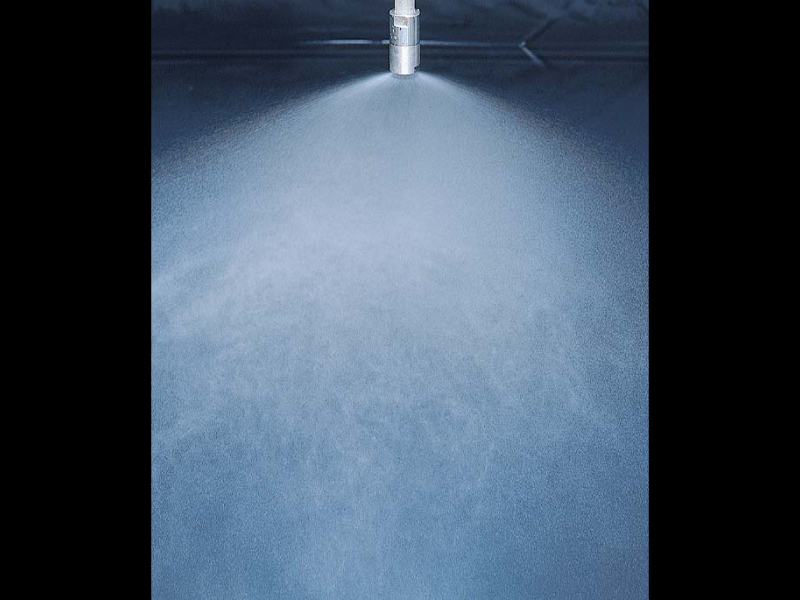

TWAA series Bi-directional, Hollow cone, slurry spray nozzles

- Semi Dry FGD solutions:

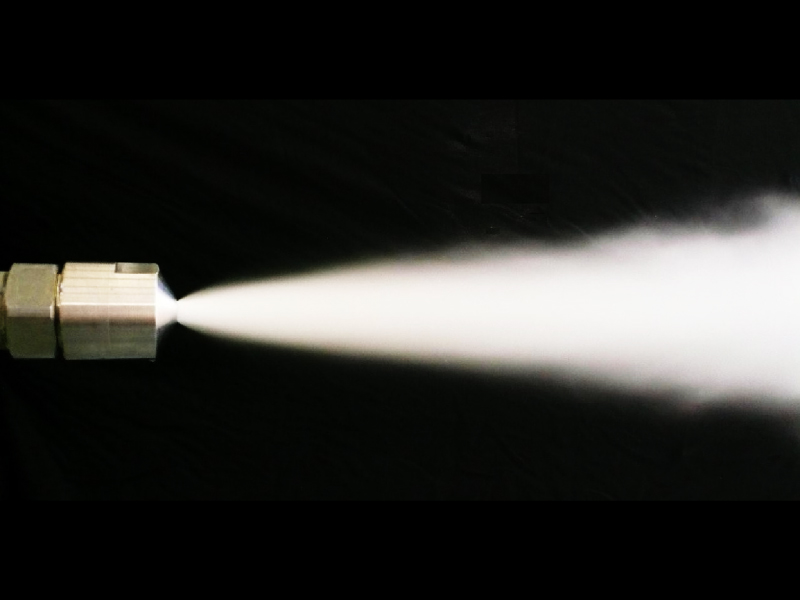

GSPB series Spillback nozzles (Large flow, high-pressure return)

SPB series Spillback nozzles (with variable flow)

GSIMII series with Alumina tip (AL99) – Large Capacity Fine Fog Nozzles/ Full Cone Spray

Solutions

Benefits

- Simpler equipment layout

- Less maintenance = time savings

- No wear, no corrosion during 5 years operation

TAA series nozzle spraying

TWAA series nozzle spraying

SPB series nozzle spraying

GSIMII series

Advantages of the solution

- Highly wear-resistant as made all in SiC (or SiSiC)

- Lightweight, 1/3 weight compared with stainless steel nozzles

- Large free passage diameter for minimal clogging

Main applications for these nozzles

- Absorption tower of FGD equipment

- Spraying slurry