Hydraulic Spray Nozzle

Highly wear resistance & Chemical resistance

High quality ceramic nozzles

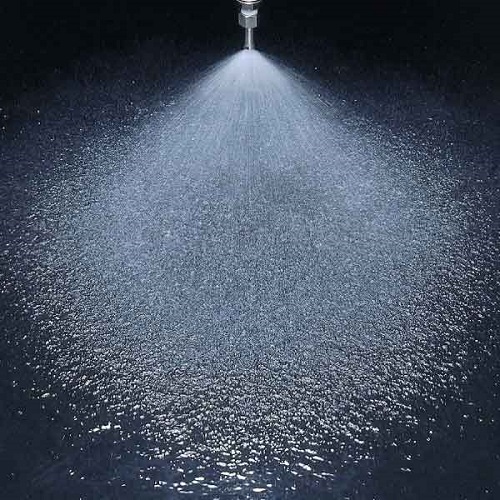

High quality ceramic nozzlesNozzles are precision tools used in many industries to spray air, water, or a mix of liquid and air. They have multiple applications such as spraying, cleaning, cooling, chemicals spraying, humidification, dust suppression, etc. Each nozzle has precise characteristics such as spray angle, spray capacity, spray pattern, and spray distribution.

The hydraulic nozzle is a single-fluid type of spray nozzle that commonly sprays water or other liquids like chemicals, honey, oil, etc. depending on the application.

We designed our hydraulic nozzles to answer our customer’s needs. Thanks to our high range of nozzle possibilities, we have a good answer to a lot of applications :

- cleaning;

- spraying water or chemicals;

- cooling;

- paper or metal trimming, etc.

We classify hydraulic nozzles into 4 categories: flat spray pattern, hollow cone pattern, full cone pattern, and solid stream jet. These categories represent different spray patterns and each of them will be more suitable depending on the application and the results you are looking to achieve.

Guarantee of Spray Angle

In regards to the flat spray and cone spray nozzles, they are guaranteed to have a rated spray angle within the range of +/- 5°, under a standard pressure. The solid stream jet nozzles, on the other hand, have a guaranteed axis of coverage angle from the nozzle’s centerline, within a range of 3°, under a standard recommended pressure.

Furthermore, we provide hydraulic spray nozzle for a specific width request, which can either be wide spray angles or of narrower spray angles. Within these categories we recommend our cone spray nozzle and flat spray nozzle.

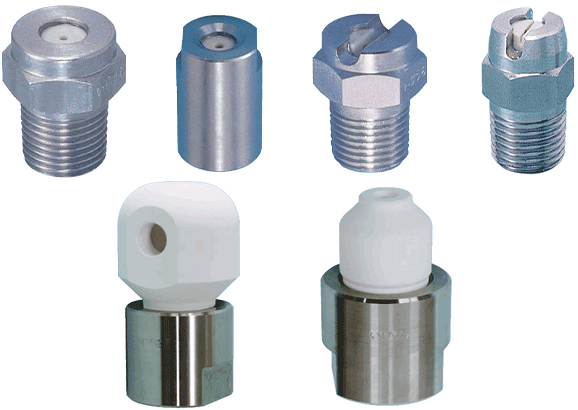

Choice of materials depending on your application

In order to satisfy the needs and applications of the customers, Ikeuchi has implemented the development of nozzles from various materials suitable for each particular request and demand. The material of construction for the parts of the nozzles can vary from stainless steel, rubber, ceramic to plastic. Depending on the usage or purpose of the nozzles, Ikeuchi provides hydraulic nozzles manufactured from various types of stainless steel, ceramic and plastic, or from a combination of materials.

Due to the overuse of nozzles or usage under unrecommended conditions, the nozzle orifices could be constantly placed under pressure of abrasion. However, for demanding applications and requirements, the ceramic spray nozzles have proven to be manufactured out of an outstanding wear-resistant material, lasting 20-30 times longer than stainless steel nozzles (advantages of ceramic nozzle).

Differences in our Cone Spray Nozzles

In the category of cone spray nozzles, we provide a wide variety of products for various applications. Based on the mean droplet diameter and the spray pattern, we can mention the sub-categories of hollow cone nozzle and full cone nozzle (solid cone spray). The difference between the two, results from the fact that the droplet size of the hollow cone spray is the smallest from the whole range of hydraulic nozzles. This leads to being used for different industries.

Moreover, the full cone spray pattern distributes the droplets in an even cone-shaped pattern reaching angles between 60-215°, depending on the model. While the hollow cone pattern angle covers a surface of up to 130°, depending on the model.

Testing the quality in a laboratory environment

Ikeuchi strives to maintain and provide high quality nozzles. That is why we are invested in the study of our products.

Of course, as a Japanese company, we pride ourselves with following the Japanese traditions and we have instilled and embedded the following 5S methodology, based on:

- sorting – the products;

- setting – the products based on category according to the models;

- shine – ensuring that the working place is organized and spotless;

- standardizing – the working processes;

- sustaining – individual initiative.

Thus, to guarantee the quality performance of our hydraulic nozzles, we test the nozzles from each batch of production for the spray angle and spray capacity in established laboratory conditions. The testing phase of our hydraulic nozzles undergoes spraying tap water under laboratory conditions at room temperature.

Based on the results of the laboratory inspection, only the nozzles that have passed the criteria for the quality standard of inspection will be shipped.

Our headquarter and factories have been ISO9001 certified, which highlights the level of quality that is implemented in the manufacturing and testing stages of our nozzles.

At IKEUCHI, we have determined the fundamentals to select the right nozzle for your application based on their characteristics. When selecting the nozzle, we advise you based on your required spray angle, spray capacity, optimum spray pattern, and spray distribution.

If you have technical question about nozzles, need advice to choose, or request a quote,