October 9, 2019

What is best about ceramic nozzles?

What are the advantages of ceramic nozzles?

Ceramic materials surround us in our everyday life. We mainly know ceramic as used in pottery or glass. However, ceramic is also an excellent material for spray nozzles due to its mechanical properties.

IKEUCHI produces full ceramic nozzles and ceramic nozzle tips from advanced ceramics. Thanks to its manufacturing process, advanced ceramic is known to be as stable and electrically conductive as metals.

What is interesting about using advanced ceramics?

End products manufactured with advanced ceramics can be categorized as high value-added products thanks to the material’s mechanical properties.

Products made from high-performance ceramics benefit from enhanced toughness and high-temperature strength.

(source: Britannica)

Firstly, here are the strong features of ceramic materials:

- Highly wear resistance

- Chemical resistance

- High rigidity

- Lighter than metallic materials

Secondly, the weak points of ceramic materials:

- Sensitive to mechanical shock

- Abruptly cooled down from high temperature (200°C), cracks may be caused

- Fluoric acid and concentrated alkali would erode ceramics

So what’s best about ceramic nozzles?

If the material used already has high-performance quality and features, spray nozzle made from advanced ceramic will therefore benefit from its quality.

Strong point of ceramic:

- High wear resistance

- Higher chemical resistance compare to metal

Wear-resistance of ceramic

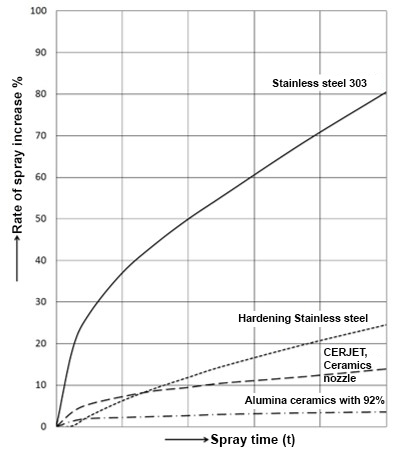

As an example, the graph on the right shows the flow rate increase in spraying with nozzles of different materials as they wear while spraying an aqueous clay solution for 100 hours. The bigger the wear, the greater the flow rate waste and associated costs.

When spraying a slurry liquid for 100 hours

- Test nozzle: Flat spray

- Spray pressure: 0.28 MPa

- Liquid type: Kaolin clay water solution liquid with 6wt%

- Spraying time: 100 hours

- Wear resistance of the ceramic nozzle

If you need or are interested in ceramic nozzle, don’t hesitate to contact us to find the adapted nozzle for your application!